Top Features

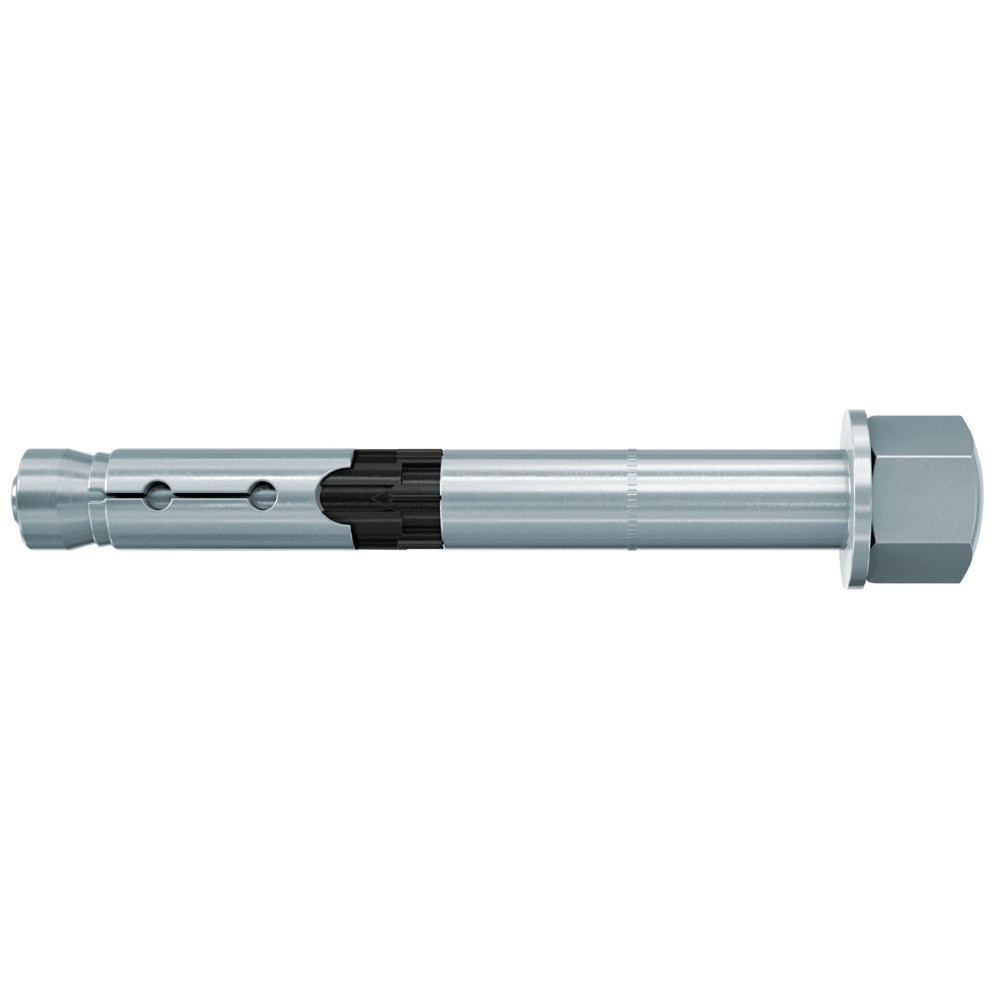

- With cover nut.

- The international approvals guarantee maximum safety and maximum performance. Also for applications in earthquake regions (seismic C1 and C2).

- The ideal combination of screw shank and sleeve enables a high transverse load capacity and fewer fixing points.

- The optimised geometry intelligently reduces the setting energy and thus ensures a force-saving assembly.

The fischer high-performance anchor FH II H with cover nut is a sleeve anchor made of zinc-plated steel. The anchor is set in the time-saving through-type installation. When tightening the anchor, the cone is pulled into the expansion sleeve and expands it against the hole wall. The black plastic ring prevents the anchor from rotating and absorbs the torque slippage. This means that the fixture is pulled towards the anchoring base. The fischer high-performance anchor FH II H with cover nut is ideally suited to fix steel constructions, machines, and gates in cracked and non-cracked concrete.

Advantages

- The international approvals guarantee maximum safety and the best performance. The European Technical Assessment even cover use in earthquake zones (seismic C1 and C2).

- The protruding head for stable and robust fixings.

- The design between the bolt and the sleeve ensures high shear load-bearing capacity. Thus, fewer fixing points are required.

- The optimised geometry intelligently reduces the energy required for assembly.

- The approval regulates the use of hollow drills.

Top Features

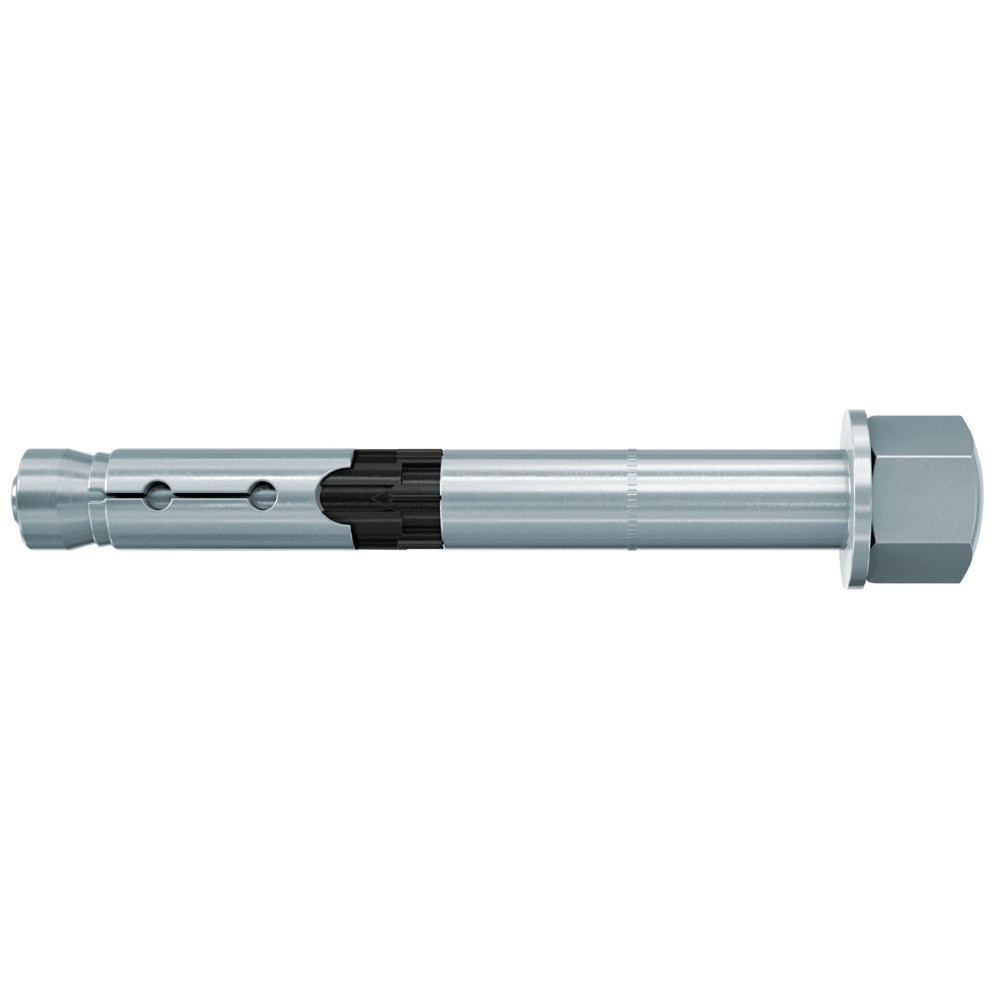

- With cover nut.

- The international approvals guarantee maximum safety and maximum performance. Also for applications in earthquake regions (seismic C1 and C2).

- The ideal combination of screw shank and sleeve enables a high transverse load capacity and fewer fixing points.

- The optimised geometry intelligently reduces the setting energy and thus ensures a force-saving assembly.

The fischer high-performance anchor FH II H with cover nut is a sleeve anchor made of zinc-plated steel. The anchor is set in the time-saving through-type installation. When tightening the anchor, the cone is pulled into the expansion sleeve and expands it against the hole wall. The black plastic ring prevents the anchor from rotating and absorbs the torque slippage. This means that the fixture is pulled towards the anchoring base. The fischer high-performance anchor FH II H with cover nut is ideally suited to fix steel constructions, machines, and gates in cracked and non-cracked concrete.

Advantages

- The international approvals guarantee maximum safety and the best performance. The European Technical Assessment even cover use in earthquake zones (seismic C1 and C2).

- The protruding head for stable and robust fixings.

- The design between the bolt and the sleeve ensures high shear load-bearing capacity. Thus, fewer fixing points are required.

- The optimised geometry intelligently reduces the energy required for assembly.

- The approval regulates the use of hollow drills.

Top Features

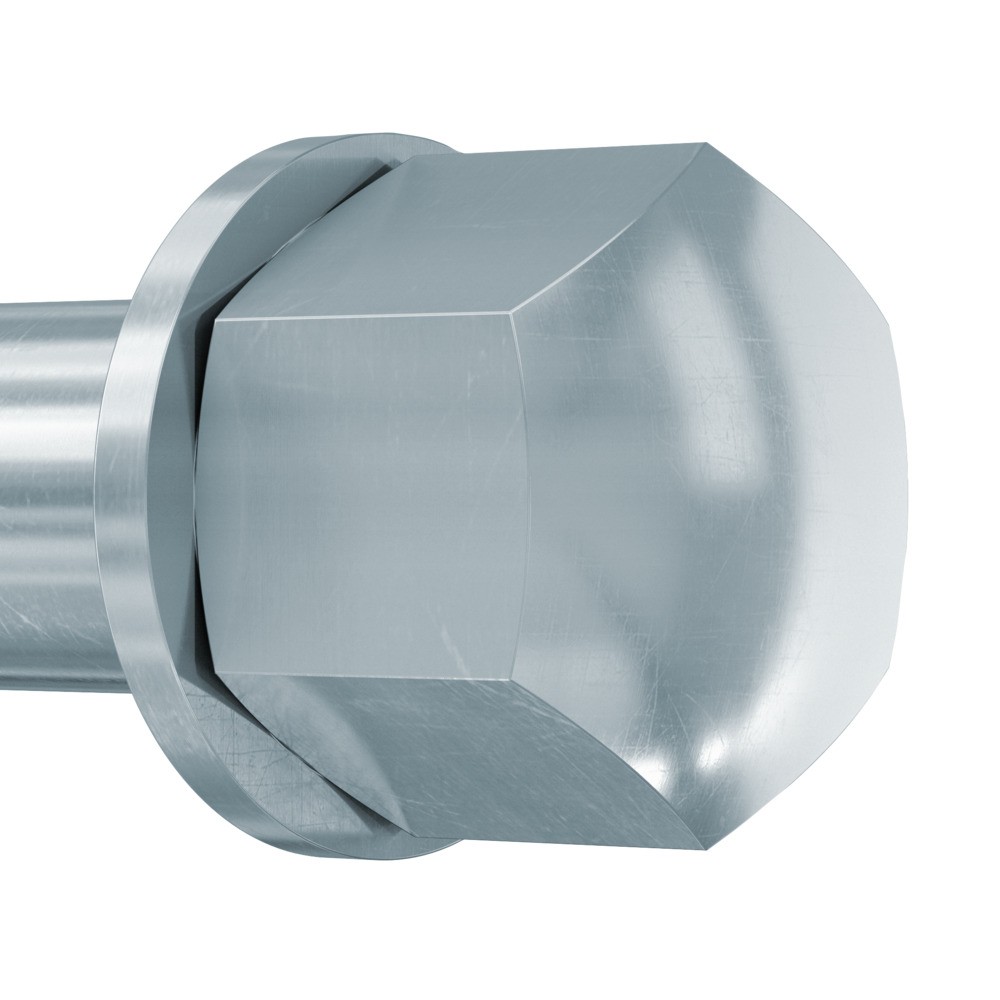

- With cover nut.

- The international approvals guarantee maximum safety and maximum performance. Also for applications in earthquake regions (seismic C1 and C2).

- The ideal combination of screw shank and sleeve enables a high transverse load capacity and fewer fixing points.

- The optimised geometry intelligently reduces the setting energy and thus ensures a force-saving assembly.

The fischer high-performance anchor FH II H with cover nut is a sleeve anchor made of zinc-plated steel. The anchor is set in the time-saving through-type installation. When tightening the anchor, the cone is pulled into the expansion sleeve and expands it against the hole wall. The black plastic ring prevents the anchor from rotating and absorbs the torque slippage. This means that the fixture is pulled towards the anchoring base. The fischer high-performance anchor FH II H with cover nut is ideally suited to fix steel constructions, machines, and gates in cracked and non-cracked concrete.

Advantages

- The international approvals guarantee maximum safety and the best performance. The European Technical Assessment even cover use in earthquake zones (seismic C1 and C2).

- The protruding head for stable and robust fixings.

- The design between the bolt and the sleeve ensures high shear load-bearing capacity. Thus, fewer fixing points are required.

- The optimised geometry intelligently reduces the energy required for assembly.

- The approval regulates the use of hollow drills.

Top Features

- With cover nut.

- The international approvals guarantee maximum safety and maximum performance. Also for applications in earthquake regions (seismic C1 and C2).

- The ideal combination of screw shank and sleeve enables a high transverse load capacity and fewer fixing points.

- The optimised geometry intelligently reduces the setting energy and thus ensures a force-saving assembly.

The fischer high-performance anchor FH II H with cover nut is a sleeve anchor made of zinc-plated steel. The anchor is set in the time-saving through-type installation. When tightening the anchor, the cone is pulled into the expansion sleeve and expands it against the hole wall. The black plastic ring prevents the anchor from rotating and absorbs the torque slippage. This means that the fixture is pulled towards the anchoring base. The fischer high-performance anchor FH II H with cover nut is ideally suited to fix steel constructions, machines, and gates in cracked and non-cracked concrete.

Advantages

- The international approvals guarantee maximum safety and the best performance. The European Technical Assessment even cover use in earthquake zones (seismic C1 and C2).

- The protruding head for stable and robust fixings.

- The design between the bolt and the sleeve ensures high shear load-bearing capacity. Thus, fewer fixing points are required.

- The optimised geometry intelligently reduces the energy required for assembly.

- The approval regulates the use of hollow drills.

Top Features

- With cover nut.

- The international approvals guarantee maximum safety and maximum performance. Also for applications in earthquake regions (seismic C1 and C2).

- The ideal combination of screw shank and sleeve enables a high transverse load capacity and fewer fixing points.

- The optimised geometry intelligently reduces the setting energy and thus ensures a force-saving assembly.

The fischer high-performance anchor FH II H with cover nut is a sleeve anchor made of zinc-plated steel. The anchor is set in the time-saving through-type installation. When tightening the anchor, the cone is pulled into the expansion sleeve and expands it against the hole wall. The black plastic ring prevents the anchor from rotating and absorbs the torque slippage. This means that the fixture is pulled towards the anchoring base. The fischer high-performance anchor FH II H with cover nut is ideally suited to fix steel constructions, machines, and gates in cracked and non-cracked concrete.

Advantages

- The international approvals guarantee maximum safety and the best performance. The European Technical Assessment even cover use in earthquake zones (seismic C1 and C2).

- The protruding head for stable and robust fixings.

- The design between the bolt and the sleeve ensures high shear load-bearing capacity. Thus, fewer fixing points are required.

- The optimised geometry intelligently reduces the energy required for assembly.

- The approval regulates the use of hollow drills.

Top Features

- With cover nut.

- The international approvals guarantee maximum safety and maximum performance. Also for applications in earthquake regions (seismic C1 and C2).

- The ideal combination of screw shank and sleeve enables a high transverse load capacity and fewer fixing points.

- The optimised geometry intelligently reduces the setting energy and thus ensures a force-saving assembly.

The fischer high-performance anchor FH II H with cover nut is a sleeve anchor made of zinc-plated steel. The anchor is set in the time-saving through-type installation. When tightening the anchor, the cone is pulled into the expansion sleeve and expands it against the hole wall. The black plastic ring prevents the anchor from rotating and absorbs the torque slippage. This means that the fixture is pulled towards the anchoring base. The fischer high-performance anchor FH II H with cover nut is ideally suited to fix steel constructions, machines, and gates in cracked and non-cracked concrete.

Advantages

- The international approvals guarantee maximum safety and the best performance. The European Technical Assessment even cover use in earthquake zones (seismic C1 and C2).

- The protruding head for stable and robust fixings.

- The design between the bolt and the sleeve ensures high shear load-bearing capacity. Thus, fewer fixing points are required.

- The optimised geometry intelligently reduces the energy required for assembly.

- The approval regulates the use of hollow drills.

Top Features

- With cover nut.

- The international approvals guarantee maximum safety and maximum performance. Also for applications in earthquake regions (seismic C1 and C2).

- The ideal combination of screw shank and sleeve enables a high transverse load capacity and fewer fixing points.

- The optimised geometry intelligently reduces the setting energy and thus ensures a force-saving assembly.

The fischer high-performance anchor FH II H with cover nut is a sleeve anchor made of zinc-plated steel. The anchor is set in the time-saving through-type installation. When tightening the anchor, the cone is pulled into the expansion sleeve and expands it against the hole wall. The black plastic ring prevents the anchor from rotating and absorbs the torque slippage. This means that the fixture is pulled towards the anchoring base. The fischer high-performance anchor FH II H with cover nut is ideally suited to fix steel constructions, machines, and gates in cracked and non-cracked concrete.

Advantages

- The international approvals guarantee maximum safety and the best performance. The European Technical Assessment even cover use in earthquake zones (seismic C1 and C2).

- The protruding head for stable and robust fixings.

- The design between the bolt and the sleeve ensures high shear load-bearing capacity. Thus, fewer fixing points are required.

- The optimised geometry intelligently reduces the energy required for assembly.

- The approval regulates the use of hollow drills.

Top Features

- With cover nut.

- The international approvals guarantee maximum safety and maximum performance. Also for applications in earthquake regions (seismic C1 and C2).

- The ideal combination of screw shank and sleeve enables a high transverse load capacity and fewer fixing points.

- The optimised geometry intelligently reduces the setting energy and thus ensures a force-saving assembly.

The fischer high-performance anchor FH II H with cover nut is a sleeve anchor made of zinc-plated steel. The anchor is set in the time-saving through-type installation. When tightening the anchor, the cone is pulled into the expansion sleeve and expands it against the hole wall. The black plastic ring prevents the anchor from rotating and absorbs the torque slippage. This means that the fixture is pulled towards the anchoring base. The fischer high-performance anchor FH II H with cover nut is ideally suited to fix steel constructions, machines, and gates in cracked and non-cracked concrete.

Advantages

- The international approvals guarantee maximum safety and the best performance. The European Technical Assessment even cover use in earthquake zones (seismic C1 and C2).

- The protruding head for stable and robust fixings.

- The design between the bolt and the sleeve ensures high shear load-bearing capacity. Thus, fewer fixing points are required.

- The optimised geometry intelligently reduces the energy required for assembly.

- The approval regulates the use of hollow drills.

Top Features

- With cover nut.

- The international approvals guarantee maximum safety and maximum performance. Also for applications in earthquake regions (seismic C1 and C2).

- The ideal combination of screw shank and sleeve enables a high transverse load capacity and fewer fixing points.

- The optimised geometry intelligently reduces the setting energy and thus ensures a force-saving assembly.

The fischer high-performance anchor FH II H with cover nut is a sleeve anchor made of zinc-plated steel. The anchor is set in the time-saving through-type installation. When tightening the anchor, the cone is pulled into the expansion sleeve and expands it against the hole wall. The black plastic ring prevents the anchor from rotating and absorbs the torque slippage. This means that the fixture is pulled towards the anchoring base. The fischer high-performance anchor FH II H with cover nut is ideally suited to fix steel constructions, machines, and gates in cracked and non-cracked concrete.

Advantages

- The international approvals guarantee maximum safety and the best performance. The European Technical Assessment even cover use in earthquake zones (seismic C1 and C2).

- The protruding head for stable and robust fixings.

- The design between the bolt and the sleeve ensures high shear load-bearing capacity. Thus, fewer fixing points are required.

- The optimised geometry intelligently reduces the energy required for assembly.

- The approval regulates the use of hollow drills.

Top Features

- With cover nut.

- The international approvals guarantee maximum safety and maximum performance. Also for applications in earthquake regions (seismic C1 and C2).

- The ideal combination of screw shank and sleeve enables a high transverse load capacity and fewer fixing points.

- The optimised geometry intelligently reduces the setting energy and thus ensures a force-saving assembly.

The fischer high-performance anchor FH II H with cover nut is a sleeve anchor made of zinc-plated steel. The anchor is set in the time-saving through-type installation. When tightening the anchor, the cone is pulled into the expansion sleeve and expands it against the hole wall. The black plastic ring prevents the anchor from rotating and absorbs the torque slippage. This means that the fixture is pulled towards the anchoring base. The fischer high-performance anchor FH II H with cover nut is ideally suited to fix steel constructions, machines, and gates in cracked and non-cracked concrete.

Advantages

- The international approvals guarantee maximum safety and the best performance. The European Technical Assessment even cover use in earthquake zones (seismic C1 and C2).

- The protruding head for stable and robust fixings.

- The design between the bolt and the sleeve ensures high shear load-bearing capacity. Thus, fewer fixing points are required.

- The optimised geometry intelligently reduces the energy required for assembly.

- The approval regulates the use of hollow drills.

Top Features

- With cover nut.

- The international approvals guarantee maximum safety and maximum performance. Also for applications in earthquake regions (seismic C1 and C2).

- The ideal combination of screw shank and sleeve enables a high transverse load capacity and fewer fixing points.

- The optimised geometry intelligently reduces the setting energy and thus ensures a force-saving assembly.

The fischer high-performance anchor FH II H with cover nut is a sleeve anchor made of zinc-plated steel. The anchor is set in the time-saving through-type installation. When tightening the anchor, the cone is pulled into the expansion sleeve and expands it against the hole wall. The black plastic ring prevents the anchor from rotating and absorbs the torque slippage. This means that the fixture is pulled towards the anchoring base. The fischer high-performance anchor FH II H with cover nut is ideally suited to fix steel constructions, machines, and gates in cracked and non-cracked concrete.

Advantages

- The international approvals guarantee maximum safety and the best performance. The European Technical Assessment even cover use in earthquake zones (seismic C1 and C2).

- The protruding head for stable and robust fixings.

- The design between the bolt and the sleeve ensures high shear load-bearing capacity. Thus, fewer fixing points are required.

- The optimised geometry intelligently reduces the energy required for assembly.

- The approval regulates the use of hollow drills.