Item No. 06100070

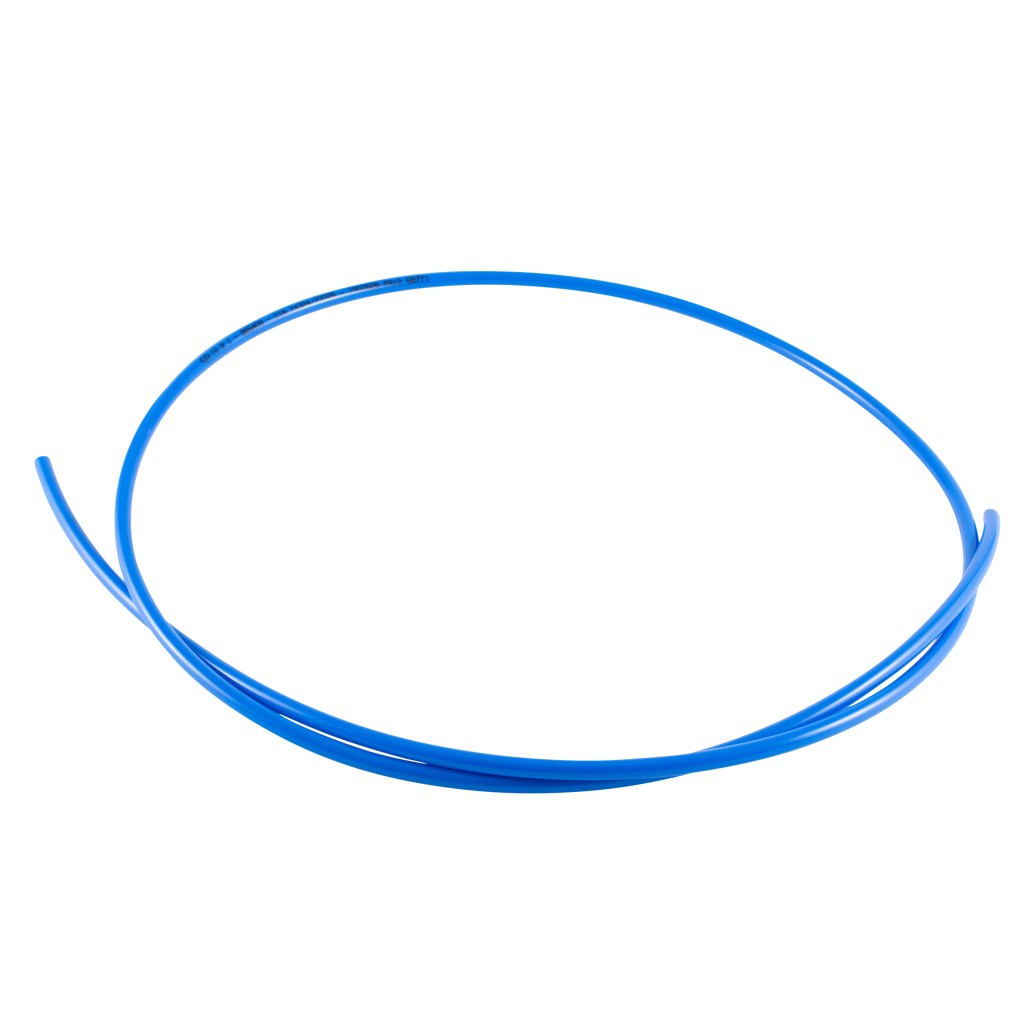

Mixer nozzle for resin injection mortars

For approval compliant installation of resin injection systems, it is guaranteed through the use of correct matched system components such as the mixer nozzles. In the case of anchoring systems with injection mortar, the two components are mixed and activated during extrusion by the mixing spiral in the mixer nozzle. The mixer nozzle guarantees a consistent mixing of the mortar components and thus enables the safety-relevant application of the resin injection mortar. The mixer nozzle closes after the cartridge has been used. A new mixer nozzle is screwed on before reuse.

Please note: Injection mortars rely on the sensitive mixer nozzle to ensure correct ratio of its formulation, when ordering spare mixer nozzles note the resin injection mortar as each type require different mixer nozzles and must match the injection mortar used.

For deeper drilled holes, extension nozzles are required to make sure the extruded resin mortar starts to fill from the bottom of the hole.

Mixer nozzle for resin injection mortars

For approval compliant installation of resin injection systems, it is guaranteed through the use of correct matched system components such as the mixer nozzles. In the case of anchoring systems with injection mortar, the two components are mixed and activated during extrusion by the mixing spiral in the mixer nozzle. The mixer nozzle guarantees a consistent mixing of the mortar components and thus enables the safety-relevant application of the resin injection mortar. The mixer nozzle closes after the cartridge has been used. A new mixer nozzle is screwed on before reuse.

Please note: Injection mortars rely on the sensitive mixer nozzle to ensure correct ratio of its formulation, when ordering spare mixer nozzles note the resin injection mortar as each type require different mixer nozzles and must match the injection mortar used.

For deeper drilled holes, extension nozzles are required to make sure the extruded resin mortar starts to fill from the bottom of the hole.

Mixer nozzle for resin injection mortars

For approval compliant installation of resin injection systems, it is guaranteed through the use of correct matched system components such as the mixer nozzles. In the case of anchoring systems with injection mortar, the two components are mixed and activated during extrusion by the mixing spiral in the mixer nozzle. The mixer nozzle guarantees a consistent mixing of the mortar components and thus enables the safety-relevant application of the resin injection mortar. The mixer nozzle closes after the cartridge has been used. A new mixer nozzle is screwed on before reuse.

Please note: Injection mortars rely on the sensitive mixer nozzle to ensure correct ratio of its formulation, when ordering spare mixer nozzles note the resin injection mortar as each type require different mixer nozzles and must match the injection mortar used.

For deeper drilled holes, extension nozzles are required to make sure the extruded resin mortar starts to fill from the bottom of the hole.

Mixer nozzle for resin injection mortars

For approval compliant installation of resin injection systems, it is guaranteed through the use of correct matched system components such as the mixer nozzles. In the case of anchoring systems with injection mortar, the two components are mixed and activated during extrusion by the mixing spiral in the mixer nozzle. The mixer nozzle guarantees a consistent mixing of the mortar components and thus enables the safety-relevant application of the resin injection mortar. The mixer nozzle closes after the cartridge has been used. A new mixer nozzle is screwed on before reuse.

Please note: Injection mortars rely on the sensitive mixer nozzle to ensure correct ratio of its formulation, when ordering spare mixer nozzles note the resin injection mortar as each type require different mixer nozzles and must match the injection mortar used.

For deeper drilled holes, extension nozzles are required to make sure the extruded resin mortar starts to fill from the bottom of the hole.

Mixer nozzle for resin injection mortars

For approval compliant installation of resin injection systems, it is guaranteed through the use of correct matched system components such as the mixer nozzles. In the case of anchoring systems with injection mortar, the two components are mixed and activated during extrusion by the mixing spiral in the mixer nozzle. The mixer nozzle guarantees a consistent mixing of the mortar components and thus enables the safety-relevant application of the resin injection mortar. The mixer nozzle closes after the cartridge has been used. A new mixer nozzle is screwed on before reuse.

Please note: Injection mortars rely on the sensitive mixer nozzle to ensure correct ratio of its formulation, when ordering spare mixer nozzles note the resin injection mortar as each type require different mixer nozzles and must match the injection mortar used.

For deeper drilled holes, extension nozzles are required to make sure the extruded resin mortar starts to fill from the bottom of the hole.

Mixer nozzle for resin injection mortars

For approval compliant installation of resin injection systems, it is guaranteed through the use of correct matched system components such as the mixer nozzles. In the case of anchoring systems with injection mortar, the two components are mixed and activated during extrusion by the mixing spiral in the mixer nozzle. The mixer nozzle guarantees a consistent mixing of the mortar components and thus enables the safety-relevant application of the resin injection mortar. The mixer nozzle closes after the cartridge has been used. A new mixer nozzle is screwed on before reuse.

Please note: Injection mortars rely on the sensitive mixer nozzle to ensure correct ratio of its formulation, when ordering spare mixer nozzles note the resin injection mortar as each type require different mixer nozzles and must match the injection mortar used.

For deeper drilled holes, extension nozzles are required to make sure the extruded resin mortar starts to fill from the bottom of the hole.

We use cookies to remember your settings, personalise content, improve website performance, analyse traffic and assist with our general marketing efforts. Learn more

Cookies are small text files that can be used by websites to improve your experience and to remember settings. The law requires that your consent is given for any cookies that are not strictly necessary for the operation of this website.

Necessary cookies are cookies that are required for the operation of this website.

Other cookies not strictly necessary for the operation of this website

Selecting this option will allow us to use cookies for marketing and analytics purposes. For example Google Analytics.